Unlock the Secrets of Industrial Strength ABS 3D Printer Filament: Discover Its Power and Potential!

3D printing has revolutionized manufacturing, offering unparalleled flexibility and innovation. At the heart of this transformation lies ABS filament, a material renowned for its strength and versatility. Among the various types of ABS, industrial strength ABS 3D printer filament stands out, catering to the growing demand for durable and high-performance materials in demanding industrial applications. This article aims to explore the properties, advantages, and diverse uses of industrial strength ABS filament, providing insights into why it has become a go-to choice for professionals in various sectors. Whether you are a seasoned 3D printing expert or a curious newcomer, understanding the capabilities of industrial strength ABS filament can open doors to new possibilities in your projects.

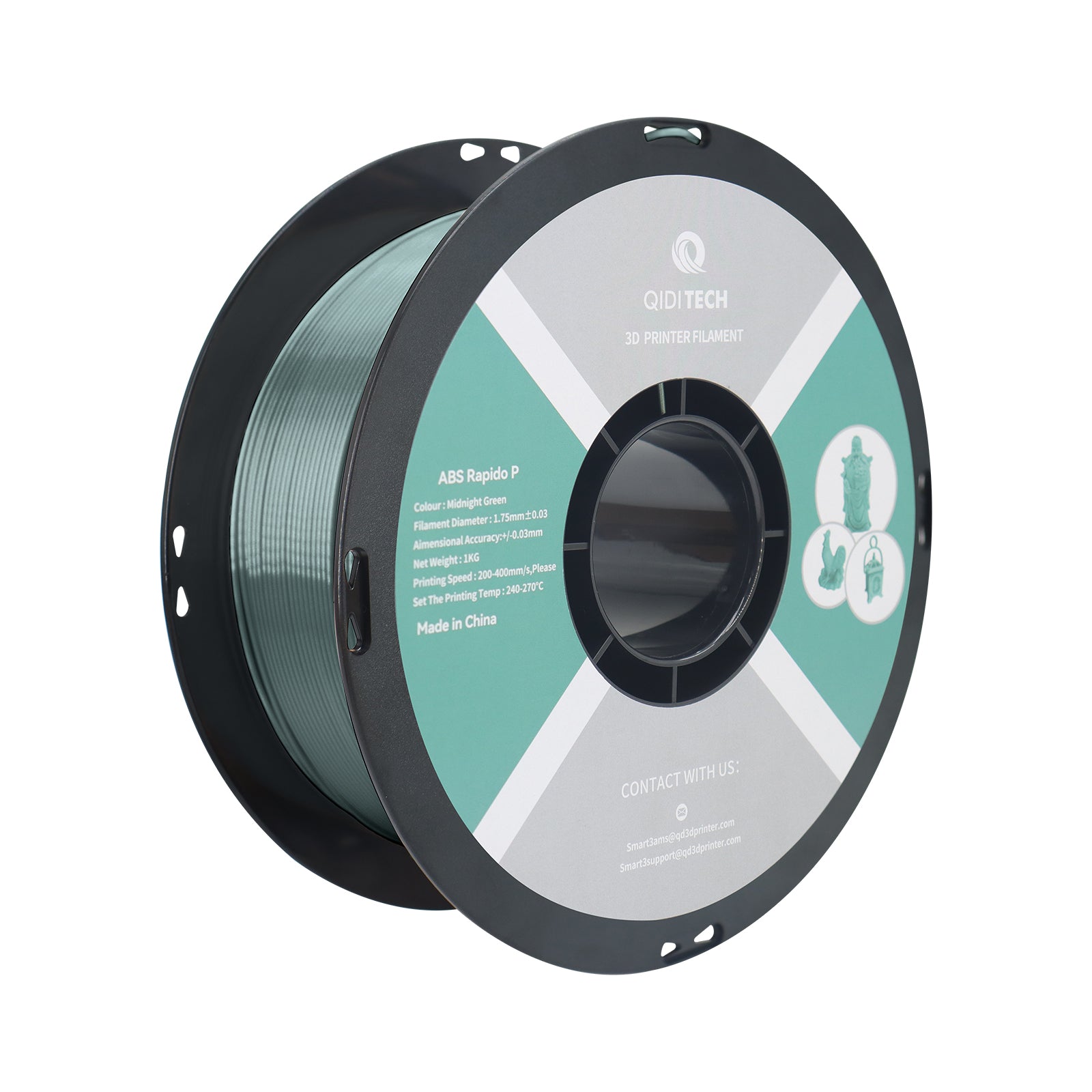

Understanding Industrial Strength ABS Filament

Industrial strength ABS filament is a specialized version of standard ABS filament, designed to meet the rigorous demands of commercial and industrial applications. While standard ABS is widely used for its affordability and ease of printing, industrial strength ABS filament is formulated to offer enhanced performance characteristics. This filament typically contains additives that improve its impact resistance, temperature tolerance, and overall durability. For instance, while standard ABS might warp or become brittle under stress, industrial strength variants maintain structural integrity even in challenging environments, making them ideal for prototypes and functional parts. A friend of mine who works in the automotive sector has shared experiences of using this filament for car components, where reliability is paramount. The added strength and resilience of industrial strength ABS filament mean that it can withstand the rigors of the automotive industry, from high temperatures to physical impacts.

Key Properties of Industrial Strength ABS Filament

The unique properties of industrial strength ABS filament make it highly suitable for demanding applications. One of its standout features is its exceptional durability, which allows it to endure mechanical stress without cracking or breaking. Additionally, this filament exhibits excellent chemical resistance, ensuring that it can withstand exposure to various substances without degrading. This feature is particularly advantageous in industries where components may come into contact with oils, solvents, or other harsh materials. Furthermore, industrial strength ABS filament is known for its ease of printing, which can be attributed to its relatively low shrinkage rate and good adhesion properties. Compared to other materials like PLA or nylon, industrial strength ABS filament strikes a balance between robustness and printability. By leveraging its properties, users can produce detailed models and functional parts with greater reliability. My friend’s workshop often utilizes this filament for creating jigs and fixtures that require precision and durability, showcasing its practical benefits in a real-world setting.

Applications of Industrial Strength ABS Filament

Industrial strength ABS filament finds its applications across a multitude of industries, thanks to its robust characteristics. In the automotive sector, it is commonly used to create prototypes and end-use parts that can withstand high temperatures and mechanical stresses. Similarly, in aerospace, this filament is favored for producing lightweight components that require both strength and precision. The manufacturing sector also benefits from industrial strength ABS filament for the production of tooling and fixtures. One notable use case is in the development of custom parts for machinery, where standard materials may fail under operational conditions. The versatility of this filament allows it to be tailored for specific projects, making it an invaluable resource. A colleague in the aerospace industry recently shared how they used industrial strength ABS to fabricate a housing component that not only performed well but also reduced overall weight, thereby enhancing the efficiency of the aircraft.

Best Practices for Using Industrial Strength ABS Filament

To achieve optimal results when printing with industrial strength ABS filament, several best practices should be considered. Firstly, ensuring an appropriate printing environment is essential, as ambient temperature can contribute to issues related to warping and deformation. Maintaining a heated bed helps improve adhesion, but it is crucial to be calibrated properly to prevent related issues. During post-processing, techniques such as sanding and smoothing can enhance the final finish of printed parts. Additionally, using acetone for post-processing can achieve better aesthetics after printing. Overall, these practices can significantly reduce warping and enhance the structural integrity of the printed product.

Summary of Industrial Strength ABS Filament Benefits

In summary, industrial strength ABS 3D printer filament is a powerful tool for professionals across various industries, combining durability, chemical resistance, and ease of use. Its robust properties make it an ideal choice for applications where performance and reliability are critical. As 3D printing technology continues to evolve, the potential for industrial strength ABS filament to transform manufacturing processes is immense. Whether you're looking to create prototypes, tooling, or functional parts, considering this filament for your projects can lead to remarkable outcomes. Embrace the future of 3D printing materials and explore the possibilities that industrial strength ABS filament can offer in your creative endeavors.