Unlock the Secrets of 3D Printing: Discover the Filaments That Will Transform Your Creations!

3D printing has revolutionized the way we create and innovate. With its growing popularity, enthusiasts and professionals alike are tapping into this technology to bring their ideas to life. However, not all 3D printing journeys are created equal, and a crucial factor in determining the success of your prints is the choice of filament. The right filament can make a significant difference in the quality, durability, and functionality of your printed objects. In this article, we will explore the various types of 3D printer filaments available, their unique properties, and how they can impact your 3D printing outcomes.

Understanding 3D Printer Filaments

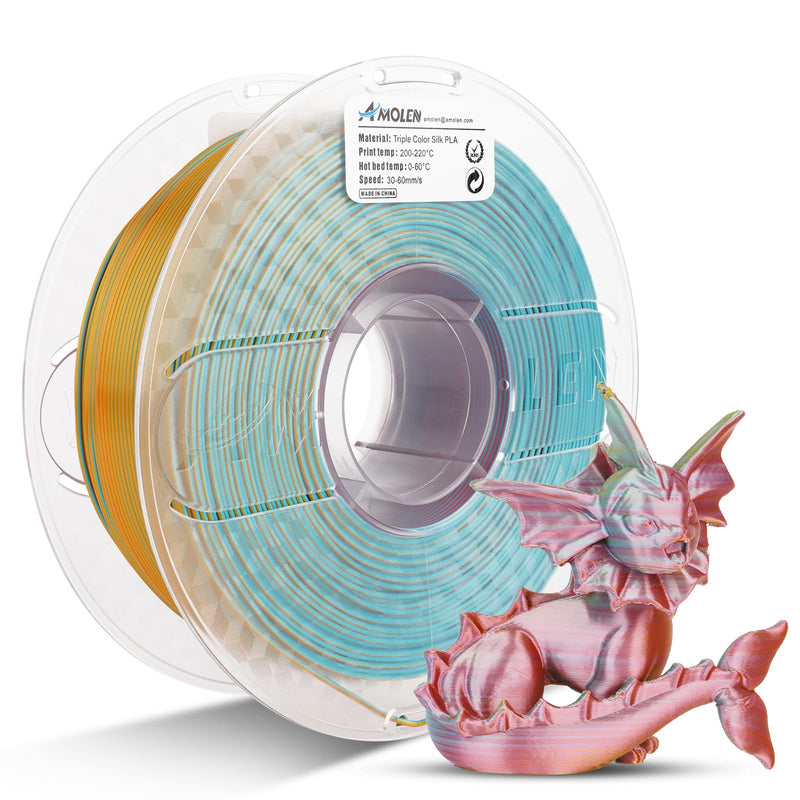

At its core, 3D printer filaments are the materials used in the 3D printing process to create objects layer by layer. These filaments are typically supplied in a spool and come in various diameters, with 1.75mm and 2.85mm being the most common. The material chosen for the filament plays a vital role in determining not only the print quality but also the physical characteristics of the final product. Different filament materials react differently to heat, environmental conditions, and stress, which can affect adhesion, layer bonding, and overall strength. Understanding these materials is essential for achieving the best 3D printer filament results in your 3D printing projects.

Types of 3D Printer Filaments

There is a plethora of 3D printer filaments available on the market, each with its own set of properties and applications. The most commonly used filaments include PLA, ABS, PETG, TPU, and Nylon. Each of these materials has distinct characteristics that make them suitable for various uses.

PLA (Polylactic Acid)

PLA is one of the most popular 3D printing filaments, especially among beginners. Known for its ease of use, it is derived from renewable resources like corn starch or sugarcane, making it biodegradable. PLA prints beautifully with a smooth finish and vibrant colors. Its low melting point allows for quick printing, but it does have limitations when it comes to heat resistance, making it less suitable for functional parts exposed to high temperatures. Common applications include prototypes, models, and decorative items.

ABS (Acrylonitrile Butadiene Styrene)

ABS is well-regarded for its strength and durability, making it ideal for functional parts and prototypes that need to withstand stress. This filament is known for its higher temperature resistance, which allows it to maintain structural integrity in hotter environments. However, printing with ABS can be challenging due to its tendency to warp and emit fumes, so proper ventilation and heated print beds are recommended. It is commonly used in automotive parts, toys, and other items that require robustness.

PETG (Polyethylene Terephthalate Glycol)

PETG strikes an excellent balance between strength and flexibility. This filament is known for its chemical resistance and is often used for applications that require food-safe prints, such as containers and utensils. The prints produced with PETG have a glossy finish and are less prone to warping compared to ABS, making it a popular choice for those looking for durability without the hassles of more complex materials.

TPU (Thermoplastic Polyurethane)

TPU is celebrated for its remarkable flexibility and rubber-like properties, which allow for the creation of soft, durable prints. This filament is perfect for items that need to bend or stretch, such as phone cases, wearable devices, and custom gaskets. While TPU can be more challenging to print with than standard rigid filaments, its unique properties open up a world of possibilities for innovative designs.

Nylon

Nylon is renowned for its exceptional strength, durability, and versatility. It is often used in engineering applications and functional parts that require resilience under stress. Nylon can absorb moisture from the air, which can affect printing, so it is essential to store it properly. Its properties make it suitable for producing gears, mechanical parts, and even textiles, showcasing the material's flexibility in various fields.

Choosing the Right Filament for Your Project

When selecting the appropriate filament for your 3D printing project, it is essential to consider the specific requirements of the task at hand. Factors such as strength, flexibility, and printability should guide your decision. For instance, if you are creating a decorative item that won't face much wear and tear, PLA would be an excellent choice. On the other hand, for functional parts that need to endure mechanical stress, ABS or Nylon may be more suitable. Assessing the end-use of your printed object will help you determine which filament aligns best with your project goals. Experimenting with different materials can also provide valuable insights into their properties and capabilities, helping you to refine your skills as a 3D printing enthusiast.

Key Takeaways on 3D Printer Filaments

In conclusion, understanding the different types of 3D printer filaments is crucial for enhancing your 3D printing results. Each material offers unique characteristics that can significantly affect the outcome of your prints. By familiarizing yourself with these options and experimenting with various filaments, you can discover what works best for your specific projects. Embrace the creativity and innovation that 3D printing offers, and let your imagination guide you in transforming your ideas into reality!